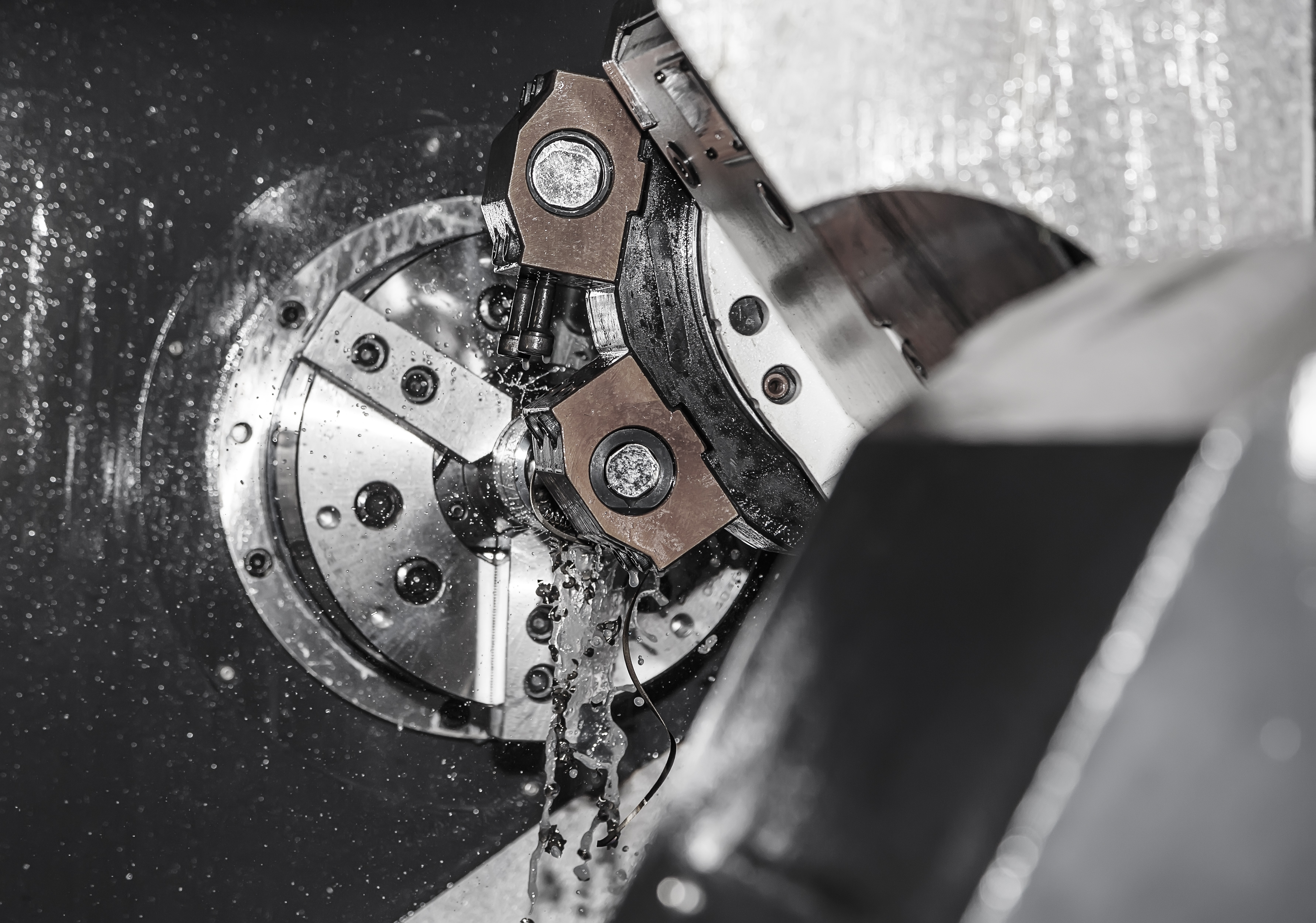

Machine Shop and Computer Numerical Control (CNC) Engineering is one of DATS’ more specialised areas of expertise, and roles in this sector are rarely the same from one day to the next. Our Machine Shop & CNC team works tirelessly to help the best candidates leave a definitive mark on this industry…

DATS’ Machine Shop & CNC team get great satisafaction from finding and delivering long-term hires who really want to push themselves for an employer – an employer who will reward them for doing so.

It’s a relatively new team for DATS but over the past twelve months or so our knoweldge of this specialist area has grown vastly.

We’ve taken the time to learn how various engineers write and upload the software in mechanical tools; how they maintain these tools over many years, ensuring their aftercare. The extent to which Offline Programmers influence the design before anything is ready for manufacturers…

It’s a diverse, highly skilled side to engineering. Our team describe how they find it hugely rewarding to unpack its complexities and attract people who are leading the industry forward in the UK.

Brexit is creating more candidate competition

Candidates tend to love the hands-on aspect of the job. Most of them work within subcontracted firms, teams, and a range of product demands. But Brexit is causing uncertainty among new workers. They’re largely worried they’ll be dropped or held back by a lack of work, or struggle to find new roles, since a fair share of employers are considered moving jobs overseas to Poland, China and elsewhere.

CNC and Machine Shop Engineers want to feel safe, valued and trusted. As such, they must fight more fiercely for the positions they want. I keep advising candidates to ask about our EU departure – how it may affect the client’s turnover, for instance – at the interview stage. By asking the right questions, a CNC Engineer can show initiative while facing up to the reality of what’s happening in the UK. They can then present their skills in the best light, and talk honestly about the longevity of a role on a perm or fixed basis.

In-house training is on the rise

Until recently, only a select few engineering firms gave their workers clear, continuous training prior to or following university. But education shouldn’t stop there. People are conscious they’ll be left behind. Perhaps it’s the inflated cost of uni degrees or the fact that so many engineers have one, but there’s a sense it’s not enough anymore.

Clients have responded. The number of in-house training schemes is growing. Candidates can learn and progress in many CNC and Machine Shop disciplines: for example, becoming a Programmer or Production Manager after cutting their teeth as an Operator for several years.

Sometimes firms seem to assume the market is oversaturated with great talent, but they’re mistaken – just a small percentage of workers are right at the top. These people are fully aware they’re sought after. That’s why they look for excellent training and personal development in a role. Independently funded courses are quite pricey, so adding them to a hiring package is a measure of trust and loyalty.

The one-stop shop is very popular

Subcontracted companies hold much sway within the industry. They act on behalf of larger firms that need CNC and Machine Shop expertise for their projects. The work is incredibly fast-paced. Candidates like these roles, as they’re moving from components that fit onto your finger to machines that are 10 feet across and weigh several tonnes. Diversity keeps things interesting.

Overall, this specialism thrives on the teams, briefs and mixture of skills that can be combined – both for small, one-off products and huge batches. Assembly Fitters, for example, are one of the positions we regularly hire for, as it lets someone work on one or several parts of a device that will be finished further down the production line.

Yet plenty of Northwest firms are a one-stop shop for CNC professionals. When they head to a fantastic recruitment partner like DATS, we can deliver opportunities that meet their ambitions and ideal work structures.

If you think our specialist Machine Shop & CNC team could help with your next role, give them a call: 01925 403800.

Benefits of Apprenticeships

Apprenticeships have long been prevalent in the engineering industry but have grown in popularity in all areas in recent years – maybe owing to the introduction of the Apprenticeship Levy in 2017. According to UCAS, there are now approximately 1500 different job role...

10 Predictions For Engineering Recruitment In 2020

The end of one decade marks a period of reflection, but it also provides a reason to look ahead. British engineering has undergone considerable change in the last 10 years. From the decline in oil and gas production to the arrival of BIM, CAD and 3D printing,...

It’s not too late to get IR35 ready

The changes to IR35 legislation come into effect in just a number of weeks now. Do you feel like you're not yet prepared? Don't worry - there's still time to get ready. And even better, we're here to help!You'll know by now that the responsibility for deciding whether...